vault backup: 2025-03-22 12:36:58

|

|

@ -14,5 +14,6 @@

|

|||

"better-export-pdf",

|

||||

"ai-image-analyzer",

|

||||

"obsidian-tasks-plugin",

|

||||

"obsidian-git"

|

||||

"obsidian-git",

|

||||

"copilot"

|

||||

]

|

||||

|

|

@ -17,6 +17,6 @@

|

|||

"repelStrength": 11.9270833333333,

|

||||

"linkStrength": 1,

|

||||

"linkDistance": 188,

|

||||

"scale": 1.4420199290482825,

|

||||

"scale": 0.6554983653232614,

|

||||

"close": true

|

||||

}

|

||||

|

|

@ -1,9 +1,11 @@

|

|||

{

|

||||

"openAIApiKey": "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",

|

||||

"isPlusUser": false,

|

||||

"plusLicenseKey": "",

|

||||

"openAIApiKey": "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",

|

||||

"openAIOrgId": "",

|

||||

"huggingfaceApiKey": "",

|

||||

"cohereApiKey": "",

|

||||

"anthropicApiKey": "",

|

||||

"anthropicModel": "claude-3-sonnet-20240229",

|

||||

"anthropicApiKey": "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",

|

||||

"azureOpenAIApiKey": "",

|

||||

"azureOpenAIApiInstanceName": "",

|

||||

"azureOpenAIApiDeploymentName": "",

|

||||

|

|

@ -11,31 +13,277 @@

|

|||

"azureOpenAIApiEmbeddingDeploymentName": "",

|

||||

"googleApiKey": "",

|

||||

"openRouterAiApiKey": "",

|

||||

"openRouterModel": "cognitivecomputations/dolphin-mixtral-8x7b",

|

||||

"defaultModel": "gpt-4-turbo-preview",

|

||||

"defaultModelDisplayName": "GPT-4 TURBO",

|

||||

"embeddingModel": "text-embedding-3-small",

|

||||

"temperature": 0.7,

|

||||

"defaultChainType": "llm_chain",

|

||||

"defaultModelKey": "gpt-4o|openai",

|

||||

"embeddingModelKey": "text-embedding-3-small|openai",

|

||||

"temperature": 0.1,

|

||||

"maxTokens": 1000,

|

||||

"contextTurns": 3,

|

||||

"contextTurns": 15,

|

||||

"userSystemPrompt": "",

|

||||

"openAIProxyBaseUrl": "",

|

||||

"openAIProxyModelName": "",

|

||||

"openAIEmbeddingProxyBaseUrl": "",

|

||||

"openAIEmbeddingProxyModelName": "",

|

||||

"ollamaModel": "llama3",

|

||||

"ollamaBaseUrl": "http://127.0.0.1:11434",

|

||||

"lmStudioBaseUrl": "http://localhost:1234/v1",

|

||||

"stream": true,

|

||||

"defaultSaveFolder": "copilot-conversations",

|

||||

"defaultConversationTag": "copilot-conversation",

|

||||

"autosaveChat": true,

|

||||

"defaultOpenArea": "view",

|

||||

"customPromptsFolder": "copilot-custom-prompts",

|

||||

"indexVaultToVectorStore": "ON MODE SWITCH",

|

||||

"qaExclusionPaths": "",

|

||||

"qaExclusions": "",

|

||||

"qaInclusions": "",

|

||||

"chatNoteContextPath": "",

|

||||

"chatNoteContextTags": [],

|

||||

"debug": true,

|

||||

"enableIndexSync": true,

|

||||

"debug": false,

|

||||

"enableEncryption": false,

|

||||

"maxSourceChunks": 3,

|

||||

"localAIModel": "",

|

||||

"ttlDays": 30,

|

||||

"embeddingProvider": "openai"

|

||||

"groqApiKey": "",

|

||||

"mistralApiKey": "",

|

||||

"activeModels": [

|

||||

{

|

||||

"name": "copilot-plus-flash",

|

||||

"provider": "copilot-plus",

|

||||

"enabled": true,

|

||||

"isBuiltIn": true,

|

||||

"core": true,

|

||||

"capabilities": [

|

||||

"vision"

|

||||

]

|

||||

},

|

||||

{

|

||||

"name": "gpt-4o",

|

||||

"provider": "openai",

|

||||

"enabled": true,

|

||||

"isBuiltIn": true,

|

||||

"core": true,

|

||||

"capabilities": [

|

||||

"vision"

|

||||

]

|

||||

},

|

||||

{

|

||||

"name": "gpt-4o-mini",

|

||||

"provider": "openai",

|

||||

"enabled": true,

|

||||

"isBuiltIn": true,

|

||||

"core": true,

|

||||

"capabilities": [

|

||||

"vision"

|

||||

]

|

||||

},

|

||||

{

|

||||

"name": "claude-3-5-sonnet-latest",

|

||||

"provider": "anthropic",

|

||||

"enabled": true,

|

||||

"isBuiltIn": true,

|

||||

"core": true,

|

||||

"capabilities": [

|

||||

"vision"

|

||||

]

|

||||

},

|

||||

{

|

||||

"name": "o1-mini",

|

||||

"provider": "openai",

|

||||

"enabled": true,

|

||||

"isBuiltIn": true,

|

||||

"capabilities": [

|

||||

"reasoning"

|

||||

]

|

||||

},

|

||||

{

|

||||

"name": "o3-mini",

|

||||

"provider": "openai",

|

||||

"enabled": true,

|

||||

"isBuiltIn": true,

|

||||

"capabilities": [

|

||||

"reasoning"

|

||||

]

|

||||

},

|

||||

{

|

||||

"name": "claude-3-5-haiku-latest",

|

||||

"provider": "anthropic",

|

||||

"enabled": true,

|

||||

"isBuiltIn": true

|

||||

},

|

||||

{

|

||||

"name": "command-r",

|

||||

"provider": "cohereai",

|

||||

"enabled": true,

|

||||

"isBuiltIn": true

|

||||

},

|

||||

{

|

||||

"name": "command-r-plus",

|

||||

"provider": "cohereai",

|

||||

"enabled": true,

|

||||

"isBuiltIn": true

|

||||

},

|

||||

{

|

||||

"name": "gemini-2.0-pro-exp",

|

||||

"provider": "google",

|

||||

"enabled": true,

|

||||

"isBuiltIn": true,

|

||||

"capabilities": [

|

||||

"vision"

|

||||

]

|

||||

},

|

||||

{

|

||||

"name": "gemini-2.0-flash",

|

||||

"provider": "google",

|

||||

"enabled": true,

|

||||

"isBuiltIn": true,

|

||||

"capabilities": [

|

||||

"vision"

|

||||

]

|

||||

},

|

||||

{

|

||||

"name": "azure-openai",

|

||||

"provider": "azure openai",

|

||||

"enabled": true,

|

||||

"isBuiltIn": true

|

||||

}

|

||||

],

|

||||

"activeEmbeddingModels": [

|

||||

{

|

||||

"name": "copilot-plus-small",

|

||||

"provider": "copilot-plus",

|

||||

"enabled": true,

|

||||

"isBuiltIn": true,

|

||||

"isEmbeddingModel": true,

|

||||

"core": true

|

||||

},

|

||||

{

|

||||

"name": "copilot-plus-large",

|

||||

"provider": "copilot-plus-jina",

|

||||

"enabled": true,

|

||||

"isBuiltIn": true,

|

||||

"isEmbeddingModel": true,

|

||||

"core": true,

|

||||

"believerExclusive": true,

|

||||

"dimensions": 1024

|

||||

},

|

||||

{

|

||||

"name": "copilot-plus-multilingual",

|

||||

"provider": "copilot-plus-jina",

|

||||

"enabled": true,

|

||||

"isBuiltIn": true,

|

||||

"isEmbeddingModel": true,

|

||||

"core": true,

|

||||

"dimensions": 512

|

||||

},

|

||||

{

|

||||

"name": "text-embedding-3-small",

|

||||

"provider": "openai",

|

||||

"enabled": true,

|

||||

"isBuiltIn": true,

|

||||

"isEmbeddingModel": true,

|

||||

"core": true

|

||||

},

|

||||

{

|

||||

"name": "text-embedding-3-large",

|

||||

"provider": "openai",

|

||||

"enabled": true,

|

||||

"isBuiltIn": true,

|

||||

"isEmbeddingModel": true

|

||||

},

|

||||

{

|

||||

"name": "embed-multilingual-light-v3.0",

|

||||

"provider": "cohereai",

|

||||

"enabled": true,

|

||||

"isBuiltIn": true,

|

||||

"isEmbeddingModel": true

|

||||

},

|

||||

{

|

||||

"name": "text-embedding-004",

|

||||

"provider": "google",

|

||||

"enabled": true,

|

||||

"isBuiltIn": true,

|

||||

"isEmbeddingModel": true

|

||||

},

|

||||

{

|

||||

"name": "azure-openai",

|

||||

"provider": "azure openai",

|

||||

"enabled": true,

|

||||

"isBuiltIn": true,

|

||||

"isEmbeddingModel": true

|

||||

}

|

||||

],

|

||||

"embeddingRequestsPerMin": 90,

|

||||

"embeddingBatchSize": 16,

|

||||

"disableIndexOnMobile": true,

|

||||

"showSuggestedPrompts": true,

|

||||

"showRelevantNotes": true,

|

||||

"numPartitions": 1,

|

||||

"promptUsageTimestamps": {},

|

||||

"defaultConversationNoteName": "{$topic}@{$date}_{$time}",

|

||||

"inlineEditCommands": [

|

||||

{

|

||||

"name": "Fix grammar and spelling",

|

||||

"prompt": "<instruction>Fix the grammar and spelling of the text below. Preserve all formatting, line breaks, and special characters. Do not add or remove any content. Return only the corrected text.</instruction>\n\n<text>{copilot-selection}</text>",

|

||||

"showInContextMenu": true

|

||||

},

|

||||

{

|

||||

"name": "Translate to Chinese",

|

||||

"prompt": "<instruction>Translate the text below into Chinese:\n 1. Preserve the meaning and tone\n 2. Maintain appropriate cultural context\n 3. Keep formatting and structure\n Return only the translated text.</instruction>\n\n<text>{copilot-selection}</text>",

|

||||

"showInContextMenu": true

|

||||

},

|

||||

{

|

||||

"name": "Summarize",

|

||||

"prompt": "<instruction>Create a bullet-point summary of the text below. Each bullet point should capture a key point. Return only the bullet-point summary.</instruction>\n\n<text>{copilot-selection}</text>",

|

||||

"showInContextMenu": true

|

||||

},

|

||||

{

|

||||

"name": "Simplify",

|

||||

"prompt": "<instruction>Simplify the text below to a 6th-grade reading level (ages 11-12). Use simple sentences, common words, and clear explanations. Maintain the original key concepts. Return only the simplified text.</instruction>\n\n<text>{copilot-selection}</text>",

|

||||

"showInContextMenu": true

|

||||

},

|

||||

{

|

||||

"name": "Emojify",

|

||||

"prompt": "<instruction>Add relevant emojis to enhance the text below. Follow these rules:\n 1. Insert emojis at natural breaks in the text\n 2. Never place two emojis next to each other\n 3. Keep all original text unchanged\n 4. Choose emojis that match the context and tone\n Return only the emojified text.</instruction>\n\n<text>{copilot-selection}</text>",

|

||||

"showInContextMenu": true

|

||||

},

|

||||

{

|

||||

"name": "Make shorter",

|

||||

"prompt": "<instruction>Reduce the text below to half its length while preserving these elements:\n 1. Main ideas and key points\n 2. Essential details\n 3. Original tone and style\n Return only the shortened text.</instruction>\n\n<text>{copilot-selection}</text>",

|

||||

"showInContextMenu": true

|

||||

},

|

||||

{

|

||||

"name": "Make longer",

|

||||

"prompt": "<instruction>Expand the text below to twice its length by:\n 1. Adding relevant details and examples\n 2. Elaborating on key points\n 3. Maintaining the original tone and style\n Return only the expanded text.</instruction>\n\n<text>{copilot-selection}</text>",

|

||||

"showInContextMenu": true

|

||||

},

|

||||

{

|

||||

"name": "Generate table of contents",

|

||||

"prompt": "<instruction>Generate a hierarchical table of contents for the text below. Use appropriate heading levels (H1, H2, H3, etc.). Include page numbers if present. Return only the table of contents.</instruction>\n\n<text>{copilot-selection}</text>",

|

||||

"showInContextMenu": false

|

||||

},

|

||||

{

|

||||

"name": "Generate glossary",

|

||||

"prompt": "<instruction>Create a glossary of important terms, concepts, and phrases from the text below. Format each entry as \"Term: Definition\". Sort entries alphabetically. Return only the glossary.</instruction>\n\n<text>{copilot-selection}</text>",

|

||||

"showInContextMenu": false

|

||||

},

|

||||

{

|

||||

"name": "Remove URLs",

|

||||

"prompt": "<instruction>Remove all URLs from the text below. Preserve all other content and formatting. URLs may be in various formats (http, https, www). Return only the text with URLs removed.</instruction>\n\n<text>{copilot-selection}</text>",

|

||||

"showInContextMenu": false

|

||||

},

|

||||

{

|

||||

"name": "Rewrite as tweet",

|

||||

"prompt": "<instruction>Rewrite the text below as a single tweet with these requirements:\n 1. Maximum 280 characters\n 2. Use concise, impactful language\n 3. Maintain the core message\n Return only the tweet text.</instruction>\n\n<text>{copilot-selection}</text>",

|

||||

"showInContextMenu": false

|

||||

},

|

||||

{

|

||||

"name": "Rewrite as tweet thread",

|

||||

"prompt": "<instruction>Convert the text below into a Twitter thread following these rules:\n 1. Each tweet must be under 240 characters\n 2. Start with \"THREAD START\" on its own line\n 3. Separate tweets with \"\n\n---\n\n\"\n 4. End with \"THREAD END\" on its own line\n 5. Make content engaging and clear\n Return only the formatted thread.</instruction>\n\n<text>{copilot-selection}</text>",

|

||||

"showInContextMenu": false

|

||||

},

|

||||

{

|

||||

"name": "Explain like I am 5",

|

||||

"prompt": "<instruction>Explain the text below in simple terms that a 5-year-old would understand:\n 1. Use basic vocabulary\n 2. Include simple analogies\n 3. Break down complex concepts\n Return only the simplified explanation.</instruction>\n\n<text>{copilot-selection}</text>",

|

||||

"showInContextMenu": false

|

||||

},

|

||||

{

|

||||

"name": "Rewrite as press release",

|

||||

"prompt": "<instruction>Transform the text below into a professional press release:\n 1. Use formal, journalistic style\n 2. Include headline and dateline\n 3. Follow inverted pyramid structure\n Return only the press release format.</instruction>\n\n<text>{copilot-selection}</text>",

|

||||

"showInContextMenu": false

|

||||

}

|

||||

]

|

||||

}

|

||||

|

|

@ -54,8 +54,8 @@

|

|||

"env": {},

|

||||

"showExportProgressBar": true,

|

||||

"lastExportDirectory": {

|

||||

"win32": "C:\\Users\\migue\\Downloads"

|

||||

"win32": "C:\\Trabajo\\VM\\Per Tody"

|

||||

},

|

||||

"lastExportType": "Html",

|

||||

"lastExportType": "Markdown",

|

||||

"showOverwriteConfirmation": true

|

||||

}

|

||||

|

|

@ -4,79 +4,24 @@

|

|||

"type": "split",

|

||||

"children": [

|

||||

{

|

||||

"id": "2d9f391e67d145b7",

|

||||

"id": "72956f0bde9f56df",

|

||||

"type": "tabs",

|

||||

"children": [

|

||||

{

|

||||

"id": "09181b0d83b4925e",

|

||||

"type": "leaf",

|

||||

"state": {

|

||||

"type": "excalidraw",

|

||||

"state": {

|

||||

"file": "05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/T300881 Layout.md"

|

||||

},

|

||||

"icon": "excalidraw-icon",

|

||||

"title": "T300881 Layout"

|

||||

}

|

||||

},

|

||||

{

|

||||

"id": "9aadee275d68ae01",

|

||||

"id": "3a65ed268f372bf1",

|

||||

"type": "leaf",

|

||||

"state": {

|

||||

"type": "markdown",

|

||||

"state": {

|

||||

"file": "05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/T300881 - Notes.md",

|

||||

"mode": "preview",

|

||||

"source": false

|

||||

},

|

||||

"icon": "lucide-file",

|

||||

"title": "T300881 - Notes"

|

||||

}

|

||||

},

|

||||

{

|

||||

"id": "8483d5ec9497d3d0",

|

||||

"type": "leaf",

|

||||

"state": {

|

||||

"type": "markdown",

|

||||

"state": {

|

||||

"file": "05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/MOVIGEAR.md",

|

||||

"file": "03-VM/33 - 9.402x - Shibuya/Notes for techinician on site/9.402x - Notes for technician on site - CARTON REJECT SYSTEM.md",

|

||||

"mode": "source",

|

||||

"source": false

|

||||

},

|

||||

"icon": "lucide-file",

|

||||

"title": "MOVIGEAR"

|

||||

}

|

||||

},

|

||||

{

|

||||

"id": "3b994882defa63e6",

|

||||

"type": "leaf",

|

||||

"state": {

|

||||

"type": "markdown",

|

||||

"state": {

|

||||

"file": "01-Documentation/Inverters/SEW/SEW Positioning SETUP/SEW Positioning SETUP.md",

|

||||

"mode": "source",

|

||||

"source": false

|

||||

},

|

||||

"icon": "lucide-file",

|

||||

"title": "SEW Positioning SETUP"

|

||||

}

|

||||

},

|

||||

{

|

||||

"id": "3669f45f34bb6753",

|

||||

"type": "leaf",

|

||||

"state": {

|

||||

"type": "markdown",

|

||||

"state": {

|

||||

"file": "05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/T300881 - LINAK - Guides.md",

|

||||

"mode": "source",

|

||||

"source": false

|

||||

},

|

||||

"icon": "lucide-file",

|

||||

"title": "T300881 - LINAK - Guides"

|

||||

"title": "9.402x - Notes for technician on site - CARTON REJECT SYSTEM"

|

||||

}

|

||||

}

|

||||

],

|

||||

"currentTab": 1

|

||||

]

|

||||

}

|

||||

],

|

||||

"direction": "vertical"

|

||||

|

|

@ -108,7 +53,7 @@

|

|||

"state": {

|

||||

"type": "search",

|

||||

"state": {

|

||||

"query": "",

|

||||

"query": "tilter",

|

||||

"matchingCase": false,

|

||||

"explainSearch": false,

|

||||

"collapseAll": false,

|

||||

|

|

@ -143,7 +88,7 @@

|

|||

}

|

||||

],

|

||||

"direction": "horizontal",

|

||||

"width": 234.5

|

||||

"width": 375.5

|

||||

},

|

||||

"right": {

|

||||

"id": "403186784ae0fd88",

|

||||

|

|

@ -211,16 +156,6 @@

|

|||

"title": "Outline of 9.3953 - Omega - Mexico - (Allen Bradley) Notes"

|

||||

}

|

||||

},

|

||||

{

|

||||

"id": "a377567fec0ebdcb",

|

||||

"type": "leaf",

|

||||

"state": {

|

||||

"type": "copilot-chat-view",

|

||||

"state": {},

|

||||

"icon": "lucide-file",

|

||||

"title": "Plugin no longer active"

|

||||

}

|

||||

},

|

||||

{

|

||||

"id": "c5697fe67da1824d",

|

||||

"type": "leaf",

|

||||

|

|

@ -231,26 +166,6 @@

|

|||

"title": "Advanced Tables"

|

||||

}

|

||||

},

|

||||

{

|

||||

"id": "00dd074372c8e96e",

|

||||

"type": "leaf",

|

||||

"state": {

|

||||

"type": "smart-connections-view",

|

||||

"state": {},

|

||||

"icon": "lucide-file",

|

||||

"title": "Plugin no longer active"

|

||||

}

|

||||

},

|

||||

{

|

||||

"id": "18332e24b3a7614f",

|

||||

"type": "leaf",

|

||||

"state": {

|

||||

"type": "smart-connections-chat-view",

|

||||

"state": {},

|

||||

"icon": "lucide-file",

|

||||

"title": "Plugin no longer active"

|

||||

}

|

||||

},

|

||||

{

|

||||

"id": "744fd26759351c55",

|

||||

"type": "leaf",

|

||||

|

|

@ -260,9 +175,19 @@

|

|||

"icon": "git-pull-request",

|

||||

"title": "Source Control"

|

||||

}

|

||||

},

|

||||

{

|

||||

"id": "671ae51c0d02a45e",

|

||||

"type": "leaf",

|

||||

"state": {

|

||||

"type": "copilot-chat-view",

|

||||

"state": {},

|

||||

"icon": "message-square",

|

||||

"title": "Copilot"

|

||||

}

|

||||

}

|

||||

],

|

||||

"currentTab": 8

|

||||

"currentTab": 4

|

||||

}

|

||||

],

|

||||

"direction": "horizontal",

|

||||

|

|

@ -285,56 +210,58 @@

|

|||

"pdf-plus:PDF++: Toggle auto-paste": false,

|

||||

"publish:Publish changes...": false,

|

||||

"obsidian-excalidraw-plugin:New drawing": false,

|

||||

"obsidian-git:Open Git source control": false

|

||||

"obsidian-git:Open Git source control": false,

|

||||

"copilot:Open Copilot Chat": false

|

||||

}

|

||||

},

|

||||

"active": "9aadee275d68ae01",

|

||||

"active": "3a65ed268f372bf1",

|

||||

"lastOpenFiles": [

|

||||

"01-Documentation/Inverters/Siemens/Setup New Siemens G120C Motors - Vetromeccanica.md",

|

||||

"01-Documentation/Inverters/Siemens/Siemens G120c - Changing the line voltage and line frequency of the SINAMICS system for the country of destination.md",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/T300881 Layout.md",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/T300881 - Notes.md",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/Interroll - Multicontrol.md",

|

||||

"03-VM/40 - 93040 - HENKEL - NEXT + 1 Problem/cronologia.md",

|

||||

"04-SIDEL/04 - E5.007299 - Modifica O&U - RNF032/Reporte/E5.007299 - Modifica O&U - RNF032 - NOTES.md",

|

||||

"01-Documentation/SIEMENS & WINCC/PLC Siemens/Siemens Delete the memory card (MC) - using Prommer.md",

|

||||

"01-Documentation/SIEMENS & WINCC/PLC Siemens/adjuntos/Pasted image 20250321160412.png",

|

||||

"01-Documentation/SIEMENS & WINCC/PLC Siemens/adjuntos/Pasted image 20250321160258.png",

|

||||

"01-Documentation/SIEMENS & WINCC/PLC Siemens/adjuntos/Pasted image 20250321160203.png",

|

||||

"01-Documentation/SIEMENS & WINCC/PLC Siemens/adjuntos/Pasted image 20250321160124.png",

|

||||

"01-Documentation/SIEMENS & WINCC/PLC Siemens/adjuntos/Pasted image 20250321160103.png",

|

||||

"04-SIDEL/04 - E5.007299 - Modifica O&U - RNF032/Reporte/adjuntos/Pasted image 20250321152823.png",

|

||||

"04-SIDEL/04 - E5.007299 - Modifica O&U - RNF032/Reporte/adjuntos",

|

||||

"04-SIDEL/00 - MASTER/Reporte",

|

||||

"04-SIDEL/00 - MASTER",

|

||||

"04-SIDEL/03 - 5.007382-EXMU01UF - RVU008 - EQPT24731/Reporte/5.007382-EXMU01UF - RVU008 - EQPT24731 - Notes.md",

|

||||

"03-VM/22 - 9.3841 - Sidel - Tilting/9.3841 - Sidel - Tilting - Notes for technician on site.md",

|

||||

"04-SIDEL/03 - 5.007382-EXMU01UF - RVU008 - EQPT24731/Reporte/adjuntos/Pasted image 20250320213656.png",

|

||||

"04-SIDEL/03 - 5.007382-EXMU01UF - RVU008 - EQPT24731/Reporte/adjuntos/Pasted image 20250320213610.png",

|

||||

"04-SIDEL/03 - 5.007382-EXMU01UF - RVU008 - EQPT24731/Reporte/adjuntos/Pasted image 20250320213405.png",

|

||||

"04-SIDEL/03 - 5.007382-EXMU01UF - RVU008 - EQPT24731/Reporte/adjuntos/Pasted image 20250320213337.png",

|

||||

"04-SIDEL/03 - 5.007382-EXMU01UF - RVU008 - EQPT24731/Reporte/5.007382-EXMU01UF - RVU008 - EQPT24731 - Initial Data.md",

|

||||

"03-VM/22 - 9.3841 - Sidel - Tilting/9.3841 - Sidel - Tilting - Data.md",

|

||||

"01-Documentation/SIDEL/SIDEL - FLD.md",

|

||||

"01-Documentation/SIEMENS & WINCC/PLC Siemens/Why is the installation of S7 Distributed Safety V5.4 aborted in Windows 7 Windows 10 EnterpriseProfessional 64-bit.md",

|

||||

"01-Documentation/SIEMENS & WINCC/PLC Siemens/Format SD procedure.md",

|

||||

"01-Documentation/SIEMENS & WINCC/PLC Siemens/PLC Siemens - Password difference.md",

|

||||

"01-Documentation/Inverters/Danfoss/Factory reset parameters.md",

|

||||

"04-SIDEL/04 - E5.007299 - Modifica O&U - RNF032/Reporte",

|

||||

"04-SIDEL/04 - E5.007299 - Modifica O&U - RNF032",

|

||||

"04-SIDEL/03 - 5.007382-EXMU01UF - RVU008 - EQPT24731/Reporte/adjuntos",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/T300881 - LINAK - Guides.md",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/MOVIGEAR.md",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/adjuntos/Pasted image 20250314150328.png",

|

||||

"01-Documentation/Inverters/SEW/SEW Positioning SETUP/SEW Positioning SETUP.md",

|

||||

"01-Documentation/Inverters/SEW/SEW Autotuning - PID - Determine load moment of inertia.md",

|

||||

"01-Documentation/Vetromeccanica/Minimotor - FC6/Minimotor - Encoder setup.md",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/Drawing 2025-03-12 21.31.49.excalidraw.md",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/adjuntos/Pasted image 20250314101512.png",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/adjuntos/Pasted image 20250314101437.png",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/adjuntos/Pasted image 20250314100128.png",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/adjuntos/Pasted image 20250314091919.png",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/adjuntos/Pasted image 20250313174827.png",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/adjuntos/Pasted image 20250313151718.png",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/adjuntos/Pasted image 20250313150710.png",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/adjuntos/Pasted image 20250313150620.png",

|

||||

"01-Documentation/Facturazion/DURC.md",

|

||||

"01-Documentation/Facturazion/Facturazion Electronica - Fatturazione Elecctronica.md",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/adjuntos/Pasted image 20250313131015.png",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/T300881 - Notes.md",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/Buffer Logic.md",

|

||||

"01-Documentation/AllenBradley Rockwell/PLC/EDS Install.md",

|

||||

"03-VM/HENKEL/93040 - HENKEL - BowlingGreen/Description/AUTEFA/AUTEFA - TG10-60 Telegrams & Triggers.md",

|

||||

"03-VM/HENKEL/93040 - HENKEL - BowlingGreen/Description/AUTEFA/AUTEFA Logic/FC TTOP AUTEFA 2 PH - FC602.md",

|

||||

"03-VM/HENKEL/93040 - HENKEL - BowlingGreen/Description/HENKEL - ALPLA - AUTEFA - Batch Data/Table ALPAL - SKU Data.md",

|

||||

"03-VM/HENKEL/93040 - HENKEL - BowlingGreen/Description/HENKEL - ALPLA - AUTEFA - Batch Data/Table - HENKEL - Vetromeccancia - EbConvey.md",

|

||||

"03-VM/HENKEL/93040 - HENKEL - BowlingGreen/Description/HENKEL - ALPLA - AUTEFA - Batch Data/Table - Batch Life cycle - Henkel - Alpla - Autefa.md",

|

||||

"03-VM/HENKEL/93040 - HENKEL - BowlingGreen/Description/HENKEL - ALPLA - AUTEFA - Batch Data/HENKEL - ALPLA - AUTEFA - Data & Batch Management System.md",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/adjuntos/adjuntos",

|

||||

"01-Documentation/PILZ/PILZ PLC Safety.md",

|

||||

"01-Documentation/Inverters/SEW/SEW Positioning SETUP/adjuntos",

|

||||

"01-Documentation/Inverters/SEW/SEW Positioning SETUP",

|

||||

"01-Documentation/AllenBradley Rockwell/Update Firmwares.md",

|

||||

"01-Documentation/PILZ",

|

||||

"01-Documentation/AllenBradley Rockwell/PLC/EDS Install.md",

|

||||

"01-Documentation/AllenBradley Rockwell/PLC/PLC Rockwell - Allen Bradley - Commissioning - Startup - Colaudo.md",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte/adjuntos",

|

||||

"04-SIDEL/01 - SAE463 - E5.006894-EXMU01UM - New Anton Paar/SAE463 - Connection SETUP.md",

|

||||

"01-Documentation/SIDEL/SIDEL - FLD.md",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica/Reporte",

|

||||

"05-COMS/01 - T300881 - Nestle SudAfrica",

|

||||

"05-COMS",

|

||||

"01-Documentation/SIEMENS & WINCC/PLC Siemens/PLC Siemens - Password difference.md",

|

||||

"04-SIDEL/01 - SAE463 - E5.006894-EXMU01UM - New Anton Paar/SAE463.md",

|

||||

"04-SIDEL/02 - SAE274 - TIA/Reporte",

|

||||

"04-SIDEL/02 - SAE274 - TIA",

|

||||

"01-Documentation/Anton Paar/Cobrix 5500/Anton Paar - Cobrix 5500.md",

|

||||

"04-SIDEL/01 - SAE463 - E5.006894-EXMU01UM - New Anton Paar/SAE463 - New Anton Paar.md",

|

||||

"01-Documentation/Scripts Python/Siemens HMI Translate - Python - LLM - Google Translate.md",

|

||||

"41 - 94154 - Update Multilane Table/94154 - Acmi - Spagna.md",

|

||||

"01-Documentation/Vetromeccanica/SEW Movigear - Max Hz from 166 hz to 133 hz.md",

|

||||

"01-Documentation/Vetromeccanica/Tavolo Acumulo Multivia/Tavolo Acumulo Multivia - FC5000 - DB5000 - New Version.md",

|

||||

"41 - 94154 - Update Multilane Table/Drawing 2025-02-25 18.12.26.excalidraw.md",

|

||||

"03-Revised/93789 Sipa Italia - Tinny - HSCounters - Piattaforma/Divider/Untitled.canvas",

|

||||

"04-InLavoro/9..... MASTER Transport/Standard Transport/FB500 Logic.canvas",

|

||||

"04-InLavoro/HENKEL/93040 - HENKEL - BowlingGreen/TL22-L25/Synoptic Change/Q3.canvas",

|

||||

|

|

|

|||

|

|

@ -1,4 +1,8 @@

|

|||

|

||||

![[Pasted image 20250317131751.png]]

|

||||

|

||||

![[Pasted image 20250317131816.png]]

|

||||

|

||||

### RSNetWorks

|

||||

|

||||

![[Pasted image 20250312113510.png]]

|

||||

|

After Width: | Height: | Size: 21 KiB |

|

After Width: | Height: | Size: 26 KiB |

|

|

@ -0,0 +1,4 @@

|

|||

| |

|

||||

| --------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- |

|

||||

| Hi H,<br><br>How do you format or reset an MMC (Micro Memory Card) for SIMATIC S7-300 CPUs?<br><br>**Instructions:** <br>It is not possible for users to format an MMC. All you can do is "reset" an MMC, which **deletes all user data**. Proceed as follows.<br><br>1. The MMC is slotted in the bay of the CPU. Your CPU requests an overall reset (slow blinking of the STOP LED).<br>2. Set the switch to MRES and hold it there (approx. 9 seconds) until the STOP LED lights continuously.<br>3. Within the next 3 seconds you must let the switch go and set it again to MRES. The STOP LED now blinks during the delete procedure.<br><br>If the MMC continues to request an overall reset after the procedure described above, then it is defective.<br><br>**Note:** <br>It is only possible to reset the MMC if it contains data that is invalid for the CPU. Otherwise the MMC is only initialized by the procedure described.<br><br>**So try it to delete all the data on the MMC in another (non Failsafe) CPU with the three points above.** |

|

||||

| I hope that the answer will help, if you have still questions, don't hesitate to ask me. <br> <br>All the best, Late <br>Never say never, think in solutions, not in trouble...... |

|

||||

|

|

@ -0,0 +1,20 @@

|

|||

|

||||

|

||||

![[Pasted image 20250321160203.png]]

|

||||

|

||||

install the prommer software - Roboot

|

||||

|

||||

![[Pasted image 20250321160258.png]]

|

||||

|

||||

* Connect to the usb

|

||||

* Assign the prommer to the Memory Card Parameter

|

||||

|

||||

![[Pasted image 20250321160103.png]]

|

||||

|

||||

![[Pasted image 20250321160124.png]]

|

||||

|

||||

* Then on the Simatic Manager:

|

||||

|

||||

Completely delete the memory card (MC)Proceed as follows: 1. Slot the memory card into the programming device (PG). 2. **In the SIMATIC Manager select "File > S7-MemoryCard > Delete"**.

|

||||

|

||||

![[Pasted image 20250321160412.png]]

|

||||

|

|

@ -0,0 +1,36 @@

|

|||

# Why is the installation of S7 Distributed Safety V5.4 aborted in Windows 7 / Windows 10 Enterprise/Professional 64-bit?

|

||||

|

||||

- Entry

|

||||

|

||||

- Associated product(s)

|

||||

|

||||

|

||||

**Description

|

||||

**For the installation of S7 Distributed Safety V5.4 (SP5 + Update 1 onwards)keep to the procedure described below by

|

||||

|

||||

- installing first S7 Distributed Safety V5.4 and

|

||||

- then WinCC.

|

||||

|

||||

If you have installed WinCC before S7 Distributed Safety V5.4 or you get the error message "The wizard was aborted before S7 Distributed Safety Programming could be installed completely", proceed as follows to install in the given order.

|

||||

|

||||

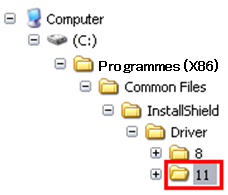

1. Open the Explorer in Windows and mark the folder

|

||||

C:\Programs(x86)\Common Files\InstallShield\Driver\11

|

||||

**Note

|

||||

**Parts of the path might be hidden depending on the setting.

|

||||

|

||||

|

||||

Fig. 01

|

||||

|

||||

2. Rename folder "11" (arbitrary name).

|

||||

3. Install S7 Distributed Safety V5.4.

|

||||

**Note**

|

||||

S7 Distributed Safety V5.4 now also creates a folder

|

||||

C:\Programs(x86)\Common Files\InstallShield\Driver\11.

|

||||

4. Delete the folder "11" created by S7 Distributed Safety V5.4

|

||||

C:\Programs(x86)\Common Files\InstallShield\Driver\11.

|

||||

5. Change the name of the folder changed in point 2 back to

|

||||

C:\Programs(x86)\Common Files\InstallShield\Driver\11.

|

||||

**Note**

|

||||

The contents of the folders "C:\Programs(x86)\Common Files\InstallShield\Driver\11" is thus restored to as it was before S7 Distributed Safety V5.4 was installed.

|

||||

|

||||

https://support.industry.siemens.com/cs/document/70968313/why-is-the-installation-of-s7-distributed-safety-v5-4-aborted-in-windows-7-windows-10-enterprise-professional-64-bit-?dti=0&lc=en-IT

|

||||

|

After Width: | Height: | Size: 34 KiB |

|

After Width: | Height: | Size: 5.1 KiB |

|

After Width: | Height: | Size: 21 KiB |

|

After Width: | Height: | Size: 42 KiB |

|

After Width: | Height: | Size: 14 KiB |

|

|

@ -0,0 +1,9 @@

|

|||

|

||||

![[Pasted image 20250320213337.png]]

|

||||

|

||||

|

||||

![[Pasted image 20250320213405.png]]

|

||||

|

||||

![[Pasted image 20250320213610.png]]

|

||||

|

||||

![[Pasted image 20250320213656.png]]

|

||||

|

After Width: | Height: | Size: 987 KiB |

|

After Width: | Height: | Size: 6.9 KiB |

|

After Width: | Height: | Size: 17 KiB |

|

After Width: | Height: | Size: 42 KiB |

|

After Width: | Height: | Size: 28 KiB |

|

After Width: | Height: | Size: 64 KiB |

|

After Width: | Height: | Size: 4.3 KiB |

|

After Width: | Height: | Size: 60 KiB |

|

|

@ -0,0 +1,56 @@

|

|||

|

||||

```

|

||||

Filler New Canfill 50 # SRNFO032

|

||||

CIP RETURN PUMP Component list

|

||||

N-1 CIP RETURN PUMP

|

||||

INSTRUMENTATION

|

||||

# PIPING AND FITTINGS FOR THE CONNECTION FILLER

|

||||

PUMP

|

||||

N-1 FLOWMETER (before the order it has to be defined with

|

||||

the customer if they want it or not)

|

||||

# ELECTRICAL EQUIPMENT (INCLUDING FREQUENCY

|

||||

# CONVERTER, CARD FOR INTERFACE WITH FREQUENCY

|

||||

# CONVERTER, ANALOG IN/OUT CARD, AUTOMATIC SWITCH,

|

||||

ADDITIONAL CONTACTS)

|

||||

|

||||

# ELECTRICAL MATERIAL FOR USE AND CONSUMPTION

|

||||

# NECESSARY DURING INSTALLATION

|

||||

# SOFTWARE MODIFICATION

|

||||

# DOCUMENTATION UPDATING

|

||||

```

|

||||

|

||||

|

||||

|

||||

|

||||

Ciao Walter

|

||||

|

||||

Ho aperto e verificato il progetto per aggiungere la parte Safety relativa al Safe OFF della pompa CIP aggiunta nel progetto.

|

||||

|

||||

La sentenza è la seguente:

|

||||

|

||||

Il Master Safety dell’epoca non prevedeva il FeedBack dello stato di Safe-OFF; infatti, a schema non è nemmeno stato aggiunto, l’ingresso.

|

||||

|

||||

Il taglio sicuro viene fatto dal PM safety già esistente, non c’è bisogno pertanto di nessuna modifica lato safety.

|

||||

|

||||

Il “problema”, metto fra virgolette, perché non credo sia così rilevante, è che nel Master PLC dell’epoca, **CFMaster**, non c’era la gestione della pompa di rilancio CIP.

|

||||

|

||||

Pertanto, ti ho già inserito ==FC136 e FB136== dal master più recente, **CMaster2**, che ti invierò assieme al progetto via Teams.

|

||||

|

||||

Il lavoro da fare è il seguente:

|

||||

|

||||

1. Aggiungere l’inverter nella configurazione Hardware

|

||||

2. Adattare FB136 al database e alle funzionalità del software dell’epoca, in parte ho cominciato, così da darti una traccia;

|

||||

|

||||

Molte cose sono però da rivedere; per esempio la FC7 aveva ancora la scalatura 0-27648 e non in frequenza, le variabili sono tutte INT e non Real come nell’attuale

|

||||

|

||||

Alcune variabili HMI le ho appoggiate negli STAT, utilizza il blocco del master per poter avere i riferimenti di quello che fanno.

|

||||

|

||||

Ciao

|

||||

|

||||

**Cristian Anversa**

|

||||

|

||||

Regular Filler Automation Engineering

|

||||

|

||||

|

||||

|

||||

![[Pasted image 20250321152823.png]]

|

||||

|

After Width: | Height: | Size: 212 KiB |

|

|

@ -0,0 +1,9 @@

|

|||

|

||||

![[Pasted image 20250316094535.png]]

|

||||

|

||||

|

||||

IN.SpeedNastroIn -> App_Speed_IN ->

|

||||

|

||||

|

||||

App_Speed_IN := Buffer.IN.SpeedNastroIn

|

||||

Buffer.STAT.CalcSpeedCatena_IN := (App_Speed_IN * Buffer.CFG.OffsetPercSpeed_CatenaIn)/100.0

|

||||

|

|

@ -0,0 +1,137 @@

|

|||

|

||||

|

||||

![[20250317_124840[1].jpg|600]]

|

||||

|

||||

![[Pasted image 20250317132119.png|850]]

|

||||

|

||||

![[Pasted image 20250317132142.png|850]]

|

||||

## Configuración del hardware

|

||||

|

||||

### Paso 1: Montaje físico del MultiControl

|

||||

|

||||

1. Monta la placa base del MultiControl en el bastidor del transportador.

|

||||

|

||||

2. Inserta los cables planos para la alimentación en la placa base:

|

||||

|

||||

- Cable plano para alimentación de lógica y sensores (L1): 24V DC

|

||||

- Cable plano para alimentación de los RollerDrive (L2): 24V DC o 48V DC según tu EC5000 BI

|

||||

3. Coloca el MultiControl sobre la placa base y asegúralo con los tornillos proporcionados.

|

||||

|

||||

|

||||

### Paso 2: Conectar el RollerDrive EC5000 BI

|

||||

|

||||

1. Conecta el RollerDrive EC5000 BI a uno de los puertos de motor del MultiControl (RD 1-4).

|

||||

2. El conector del EC5000 BI tiene la siguiente asignación de pines:

|

||||

- Pin 1: +24V/48V DC

|

||||

- Pin 2: CAN High

|

||||

- Pin 3: Tierra

|

||||

- Pin 4: CAN Low

|

||||

- Pin 5: Servicio fabricante

|

||||

|

||||

### Paso 3: Conectar sensores (si es necesario)

|

||||

|

||||

1. Conecta los sensores necesarios a los puertos "Sensor 1, I/O 1" a "Sensor 4, I/O 4" del MultiControl.

|

||||

2. Puedes usar un cable en Y para conectar un sensor y una entrada/salida adicional en la misma conexión.

|

||||

|

||||

### Paso 4: Conectar la red EtherNet/IP

|

||||

|

||||

1. Conecta un cable Ethernet al puerto "Link A" del MultiControl.

|

||||

2. Conecta el otro extremo del cable a tu red EtherNet/IP donde está el PLC ControlLogix.

|

||||

|

||||

## Configuración del MultiControl

|

||||

|

||||

### Paso 1: Acceso a la interfaz web del MultiControl

|

||||

|

||||

1. Conecta una computadora a la misma red que el MultiControl.

|

||||

2. Abre un navegador web e ingresa la dirección IP del MultiControl (por defecto: ==192.168.0.1==).

|

||||

3. Inicia sesión con las credenciales predeterminadas ==(usuario: "Interroll", contraseña: "Interroll")==.

|

||||

|

||||

### Paso 2: Configurar ajustes de red

|

||||

|

||||

1. Ve a "Network Settings" en la interfaz web.

|

||||

2. Selecciona "EtherNet/IP" como protocolo de bus.

|

||||

3. Configura la dirección IP, máscara de subred y puerta de enlace según tu red.

|

||||

4. Establece el nombre de host si es necesario.

|

||||

5. Selecciona el modo de configuración (generalmente "Static" para asignar manualmente la dirección IP).

|

||||

6. Haz clic en "Submit" para guardar los cambios.

|

||||

|

||||

|

||||

### Paso 3: Configurar ajustes del motor

|

||||

|

||||

1. Ve a "Motor Settings".

|

||||

2. Para el motor que hayas conectado (Motor 1-4), selecciona "EC5000" como tipo de motor.

|

||||

3. Configura el diámetro del rodillo (normalmente 50mm).

|

||||

4. Selecciona la relación de transmisión que corresponda a tu EC5000 BI.

|

||||

5. Configura la dirección de rotación según sea necesario.

|

||||

6. Establece la velocidad normal y alternativa según tus requisitos.

|

||||

7. Si es necesario, ajusta los valores de aceleración y deceleración.

|

||||

8. Haz clic en "Submit" para guardar los cambios.

|

||||

|

||||

### Paso 4: Configurar el programa de control

|

||||

|

||||

1. Ve a "Control Program Settings".

|

||||

2. Selecciona "I/O Device" como ID de programa para permitir que el PLC controle directamente el sistema.

|

||||

3. Configura los temporizadores si es necesario para tu aplicación específica.

|

||||

4. Haz clic en "Submit" para guardar los cambios.

|

||||

|

||||

### Paso 5: Configurar entradas/salidas digitales

|

||||

|

||||

1. Ve a "Digital I/O Settings".

|

||||

2. Configura el tipo y la polaridad de los sensores conectados.

|

||||

3. Configura las funciones de I/O adicionales según sea necesario.

|

||||

4. Haz clic en "Submit" para guardar los cambios.

|

||||

|

||||

## Configuración del PLC ControlLogix

|

||||

|

||||

### Paso 1: Instalación del archivo EDS

|

||||

|

||||

1. Descarga el archivo EDS del MultiControl desde la página web de Interroll o desde la interfaz web del MultiControl.

|

||||

2. En el software RSLogix 5000 o Studio 5000, usa la herramienta "EDS Hardware Installation Tool" para instalar el archivo EDS.

|

||||

|

||||

### Paso 2: Configuración del módulo en el proyecto

|

||||

|

||||

1. Abre tu proyecto en RSLogix 5000/Studio 5000.

|

||||

2. En la configuración de E/S, agrega un nuevo módulo Ethernet.

|

||||

3. Selecciona el MultiControl de la lista de módulos instalados.

|

||||

4. Configura la dirección IP del MultiControl.

|

||||

5. Configura el RPI (Requested Packet Interval) - generalmente 20-50ms funciona bien.

|

||||

6. Para los formatos de comunicación, selecciona las configuraciones que coincidan con los ajustes del MultiControl.

|

||||

|

||||

### Paso 3: Asignación de memoria

|

||||

|

||||

1. Crea las etiquetas en el PLC que se mapearán a las entradas y salidas del MultiControl.

|

||||

2. Para el MultiControl configurado como dispositivo I/O, necesitarás mapear:

|

||||

- Estado de los sensores

|

||||

- Control de los RollerDrive

|

||||

- Señales de estado de los RollerDrive

|

||||

- Mensajes de error

|

||||

|

||||

### Paso 4: Programación lógica

|

||||

|

||||

1. Desarrolla la lógica en el PLC para controlar el RollerDrive basado en las entradas de los sensores.

|

||||

2. Implementa la gestión de errores apropiada.

|

||||

3. Crea secuencias para el funcionamiento de tu transportador.

|

||||

|

||||

## Puesta en marcha

|

||||

|

||||

1. Comprueba todas las conexiones físicas antes de encender el sistema.

|

||||

2. Enciende la alimentación eléctrica al MultiControl.

|

||||

3. Verifica que la comunicación EtherNet/IP se establezca correctamente (el LED "Net run" debe estar encendido).

|

||||

4. Utiliza la función "Test Motor" en la interfaz web para verificar que el RollerDrive funcione correctamente.

|

||||

5. Prueba la comunicación desde el PLC enviando comandos básicos al RollerDrive.

|

||||

|

||||

## Consejos adicionales

|

||||

|

||||

1. Si tienes problemas de comunicación, verifica los ajustes de red y utiliza la función "Find Device" en la interfaz web del MultiControl.

|

||||

2. Para los EC5000 BI, asegúrate de que estén correctamente configurados con el MultiControl BI correspondiente.

|

||||

3. La configuración de tratamiento de errores (Error Handling Settings) puede ajustarse según tus necesidades.

|

||||

4. Para aplicaciones más avanzadas, puedes utilizar la función SDO (Service Data Objects) para configuraciones detalladas.

|

||||

5. Si necesitas replicar esta configuración en múltiples unidades, utiliza la función Up/Download para guardar y cargar la configuración.

|

||||

|

||||

¿Hay algún aspecto específico de la configuración sobre el que necesites más detalles?

|

||||

|

||||

|

||||

![[Pasted image 20250319181208.png]]

|

||||

|

||||

![[Pasted image 20250319182213.png]]

|

||||

![[Pasted image 20250319183245.png]]

|

||||

|

|

@ -29,4 +29,10 @@ Original:

|

|||

| | | |

|

||||

| | | |

|

||||

|

||||

![[Pasted image 20250314150328.png]]

|

||||

![[Pasted image 20250314150328.png]]

|

||||

|

||||

To reset encoder

|

||||

|

||||

![[Pasted image 20250315161104.png]]

|

||||

|

||||

![[Pasted image 20250315162517.png]]

|

||||

|

|

@ -240,14 +240,18 @@ xstEDEeppBgOqQZGoQGnrQcGQhlIZKGWhkYZWGfQA4ZeGYwmSB+dn0lhp3Qpq6AgGTk5CpwpcUxicWp/

|

|||

|

||||

57W6fIf5ITAFLsFLWpECUcRih9qb0GOpiCb+ncBfyYBmrhgKTkLEG4GRu4hKISanFzB4ZgsEuaA1m5HhpSYiD7JsOzjGlTIYhgNKMZulssTfYSaea4ppZSWmlZZpnGTRZpSWt97T6QPj6Eo++0vWmFazgRD5BujWXF79JYbh2ngudhoj4dZyPq9KY5w6cmE6SxGki6gig2RUC8g7iPoANAkwPQD6Akmdn60hs2VtEVkOLCgxCI7Gr+AE0JNJWR2Q

|

||||

|

||||

5ZP3hjI9Hn4IaKpGHMAaRBYumgihyBqdlsBDqSWimZAns6m9+/6XKHWZCoegm5kwKQ5mgpuUmDGvZeCQ5GEZR4fnbxqoWVhKGhiZnUHGKEuEf4WhagX4KVIxqUsBEM40vlm3+iNuhT6sxKRGDxo78a7BI5Drs84SA0lNDpgacedrnlZgYdjnBhIAWVqtpVhrdIwBELqMkU5seTZDx51OcIq05nhvTk9aIQch7Go/ELYQO8RgEKCzADQDADFgkgK5

|

||||

5ZP3hjI9Hn4IaKpGHMAaRBYumgihyBqdlsBDqSWimZAns6m9+/6XKHWZCoegm5kwKQ5mgpuUmDGvZeCQ5GEZR4fnbxqoWVhKGhiZnUHGKEuEf4WhagX4KVIxqUsBEM40vlm3+iNtFE+qHVBGDxo78a7BI5Drs84SA0lNDpgacedrnlZgYdjnBhIAWVqtpVhrdIwBELqMkU5seTZDx51OcIq05nhvTk9aIQch7Go/ELYQO8RgEKCzADQDADFgkgK5

|

||||

|

||||

rKAMAC6CaAsanXJ7J7jLXjuChZLSKXAFEvFCi5QhNBhSU5BMcAtIS1v2HcJs9jJEU8j6f9JyZGwNVS0eaakZZnZH6SZlfp/Hupp/pRTG6mmRi7p6nG5fpiCkyeoMZu6iBEKWnEfZGcYAqLAQgKwk7piKd+YWO1ih8zN0/UjarVxnuWubfYXUn+BQ5kiRQIh55SWHngGScCLluhfjslFUxtKTTH0pvcWBGE20UJ5I6mmuErlGJE5ka5WQa+d3pJ8b

|

||||

rKAMAC6CaAsanXJ7J7jLXjuChZLSKXAFEvFCi5QhNBhSU5BMcAtIS1v2HcJs9jJEU8j6f9JyZGwNVS0eaakZZnZH6SZlfp/Hupp/pRTG6mmRi7p6nG5fpiCkyeoMZu6iBEKWnEfZGcYAqLAQgKwk7piKd+YWO1ih8zN0/UjarVxnuWubfYXUn+BQ5kifoExRPMGHngGScCLluhfjslFUxtKTTH0pvcWBGE20UJ5I6mmuErlGJE5ka5WQa+d3pJ8b

|

||||

|

||||

6PEBcppCDykc2DUSKkCpeVq1EMgi8fymrxvUeKnkRV2DRDgAMEDCBwAcACKCYIJjtAA/AmQBUC5gSKOSAMAhAGaKjM1DlHH65lQCIANwXYPmD6AIoC4ns8WuWIXYA8hVyCKFGQFIV8uL2rIWaFlJtoVKFPEO6mn5hQHIXGF2QDoXKFgKUVRWFChUoUqFBmqnaOFJhRkDuIScdnDuFNhUoViQuCZYVGFThRkA8QdWedK+FUALYVhFFWf65BFWhX4U

|

||||

6PEBcppCDykc2DUSKkCpeVq1EMgi8fymrxvUeKnkRV2KgFwA9AGCjuIWspoDEAsOnUAUAqwIJBMQxsYsDYAt0Cwn0+e6Vv685GwDMjRZuCLcArUpsATT6Q8cKbC40G1nsCQ5MuTjSe244kpHJyKuZoxLAGBWWDmFFhbjzdBeKhKGFMWuQfnXZb2pfkgZBLCbmn5jmebk35UGXuGQpSEk5Hkc+dn8qkZbCQXGtBQ0uoq9SmKYNI86ouBmrX+peVFG

|

||||

|

||||

ZA2GG4EDAkRbYW8Fx3KwV/0aRUoXRqEqWKkoWUtuWwJFURUoVPmwKOA5AwYhYBCoggoMxS5k8UC6ijInYS6rZJsoKRDYgPTK8ABgBwEmYfAwft3xLiEAGtgGAucQwAEAW4CEjpg/MBswBkORZ4U/W0RG04MgYhbSAkABWhGCpFaxcQAigCAORDD8WxTYjEAasA+DRqgDMECcSI6iQA1okSAgT4A0SKQDKAlIAAAUFAdQALUWWB8XvFFtgACUMoJ4

|

||||

O50iUxJchtsYzJR5ifozkSA7EPNG18mgIJDJkMAAqBxgBHITScqdQGwBrRj8Y4AnwnABkLfQ3GqJQaFTrFTwmwvGq4LFgMyBQTNhbIp7BAJl0XZD6FVZDJEpgCUcdmvA+kPoUFExyR6jWFcCbYXs89hZHHIJ+uf8k2ZgKVczepKob6nOZ/qRw4Hh0KS5pS2Mgbt7UcZsasEUZWCAGAT8LkDFnqBgfuf5ZBM+RZY6BCRYSn6sxKakXPJuNBkVKJ/p

|

||||

|

||||

jKAHoCSAuMTxbgCvFSwO8VcJkJRCVnEMyH8WGYkRS4XogARToicAjuakUp4niPBA2IWVpEhZA5xdTCl52AEQD7FUyQ8CyYQhYEETwbiHsk/SCJXYDxInmMwBCgsmNGRsApxbJiaAFxatIwgykIQCMAt0GwDYgYxbiJhAwQHyU/wQmLhBGI+gBUXAQSUbcHVRu1HyUClQpTbTwY7BeRrDB4QKDDUQIANRBAAA

|

||||

OAAwQMIHABwAIoJggmO0AD8CZAFQLmBIo5IAwCEAZoqMzUOUcfrmVAIgA3Bdg+YPoAigLiYsV75ZmWiWUmXIJiUZASJXy4vaqJdgDolxJViU8Q7qe4WSM1JdkAkl2JRsUDAhJRiVYlOJQZqp2HJTSUZA7iEnHZwfJcyVYlYkLgmFAIpVAAslPEHVnnSUpTKXL6TgZKVUlRJaKUZA2GG4HslqpZyUZAoJcdysFf9AqVYl0ahKlipKFscXGlGQE+bA

|

||||

|

||||

o4DkDBwlgEKiCCgzFBjSdFVfsJFOSKYuyWOl2ID0wRZ04kxZOq3tvMjkpkpWtgGAucQwAEAW4AiAJAleYyVql0pViWClrvnhAVQcJbSAkABWhGDslmZcQAigCAORDD8uZTYjEAasA+DRqgDMECcSI6iQA1okSAgT4A0SKQDKAlIAAAUFAdQALUWWN2VdlFtgACUMoJ4jKAHoCSAuMrZbgAdlSwF2VcJM5dOVnEMyIOWGYUpdyXog4pToicASRZKU

|

||||

|

||||

p4niPBA2IWVpEhZAVZdTCl52AEQBFlUyQ8CyYUJYEETwbiHsk/Sy5XYDxInmMwBCgsmNGRsAFZbJiaA1ZatIwgykIQCMAt0GwDYgkZbiJhAwQIBU/wQmLhBGI+gLaXAQSUbcHVRu1IBXAVoFTbTwYNEOAA0owweECgw1ECADUQQAA===

|

||||

```

|

||||

%%

|

||||

|

|

@ -66,63 +66,69 @@ Actuator Connect

|

|||

|

||||

# Tabla de Datos

|

||||

|

||||

| Código | Referencia | Posición | Valor | Descripción |

|

||||

| ------ | ---------- | -------- | --------------------------- | ----------- |

|

||||

| 811B1 | 79SA1 [3] | .0 | Flc UP | |

|

||||

| 811B2 | 79SA1 [3] | .1 | Flc DW | |

|

||||

| 811B3 | 79SA1 [2] | .14 | No FaT | |

|

||||

| 811B4 | 79SA1 [2] | .15 | No FaT | |

|

||||

| 13SB4 | M36 D14 | | Flc UP | |

|

||||

| 136B2 | M36 D12 | | FTc DW | |

|

||||

| 136B3 | M36 D13 | | FiFo incluso In -2 | |

|

||||

| 138B1 | M38 D12 | | FiFo1 Home | |

|

||||

| 139S2 | M39 D12 | | FiFo1 extra corse grande | |

|

||||

| 139S3 | M39 D13 | | FiFo2 extra corse corto? | |

|

||||

| 141B1 | M41 D12 | | FiFo1 Incluso Indietro | |

|

||||

| 142B2 | M42 D13 | | FiFo2 Incluso In Corse | |

|

||||

| 139S1 | M39 D12 | | | |

|

||||

| 139S3 | M39 D13 | | | |

|

||||

| 137S2 | M37 D12 | | FiFo1 extra corse Scaricare | |

|

||||

| 137S3 | M37 D13 | | FiFo2 extra corse Scaricare | |

|

||||

| 136B4 | M36 D14 | | FoTo2 uscite piene | |

|

||||

| 143B2 | M43 D12 | | uscita M43 | |

|

||||

| 80B2 | S1A1 [6] | .13 | No FAT | |

|

||||

| 80B3 | S1A1 [6] | .14 | No FaT | |

|

||||

| 145B2 | M45 D12 | | Non uscita FaT | |

|

||||

|

||||

| Index | Código | Referencia | Posición | Descripción |

|

||||

| ---------- | -------------------- | ---------- | -------- | --------------------------- |

|

||||

| 0 | 811B1 | 79SA1 [3] | .0 | Flc UP |

|

||||

| 1 | 811B2 | 79SA1 [3] | .1 | Flc DW |

|

||||

| 2 | 811B3 | 79SA1 [2] | .14 | No FaT |

|

||||

| 3 | 811B4 | 79SA1 [2] | .15 | No FaT |

|

||||

| 4 | 13SB4 | M35 DI4 | | Flc UP |

|

||||

| 5 | 136B2 | M36 DI2 | | FTc DW |

|

||||

| 6 | 136B3 | M36 DI3 | | FiFo sicurezza ring |

|

||||

| 7 | 138B1 | M38 DI2 | | FiFo1 Home |

|

||||

| 8 | 139S2 | M39 DI2 | | FiFo1 extra corse grande |

|

||||

| 9 | 139S3 | M39 DI3 | | FiFo2 extra corse corto? |

|

||||

| 10 | 141B1 | M41 DI2 | | FiFo1 safety shuttle 1 |

|

||||

| 11 | 142B2 | M42 DI3 | | FiFo2 sicurezza navetta |

|

||||

| 12 | 139S1 | M39 DI2 | | |

|

||||

| 13 | 142B3 | M42 DI3 | | FiFo1 safety shuttle 2 |

|

||||

| 14 | 137S2 | M37 DI2 | | FiFo1 extra corse Scaricare |

|

||||

| 15 | 137S3 | M37 DI3 | | FiFo2 extra corse Scaricare |

|

||||

| 16 | 136B4 | M36 DI4 | | FoTo2 uscite piene |

|

||||

| 17 | 143B2 | M43 DI2 | | uscita M43 |

|

||||

| 18 | 80B2 | S1A1 [6] | .13 | No FAT |

|

||||

| 19 | 80B3 | S1A1 [6] | .14 | No FaT |

|

||||

| 20 | 145B2 | M45 D12 | | Non uscita FaT |

|

||||

| | | | | |

|

||||

| DigitalIN | | | | |

|

||||

| 0 | PB_Marcia | 79SA1 [1] | .12 | Marcia |

|

||||

| 1 | PB_Arresto | 79SA1 [1] | .13 | Arresto |

|

||||

| 2 | PB_Reset | 79SA1 [2] | .0 | Reset |

|

||||

| 3 | PB_Apri giù (gialle) | 79SA1 [1] | .14 | Apri giù (gialle) |

|

||||

| 4 | PB_Chiudi Verde | 79SA1 [1] | .15 | Chiudi Verde |

|

||||

| | | | | |

|

||||

| DigitalOut | | | | |

|

||||

| 0 | LAM_Marca | 79SA1 [4] | .3 | Marca |

|

||||

| 1 | LAM_Reset | 79SA1 [4] | .7 | Reset |

|

||||

| 2 | LAM_Gialle | 79SA1 [4] | .5 | Gialle |

|

||||

| 3 | LAM_Verde | 79SA1 [4] | .6 | Verde |

|

||||

| 4 | LAM_Arresto | 79SA1 [4] | .4 | Arresto |

|

||||

|

||||

|

||||

# Tabla de Datos

|

||||

FIFO

|

||||

|

||||

|Código|Referencia|Posición|Valor|Descripción|

|

||||

|---|---|---|---|---|

|

||||

|811B1|79SA1 [3]|.0|Flc UP||

|

||||

|811B2|79SA1 [3]|.1|Flc DW||

|

||||

|811B3|79SA1 [2]|.14|No FaT||

|

||||

|811B4|79SA1 [2]|.15|No FaT||

|

||||

||79SA1 [1]|.12|PB|Marca|

|

||||

||79SA1 [1]|.13|PB|Avviso|

|

||||

||79SA1 [2]|.0|PB|Reset|

|

||||

||79SA1 [1]|.14|PB|Apri giù (gialle)|

|

||||

||79SA1 [1]|.15|PB|Chiudi Verde|

|

||||

||79SA1 [4]|.3|CAM|Marca|

|

||||

||79SA1 [4]|.7|CAM|Reset|

|

||||

||79SA1 [4]|.5|CAM|Gialle|

|

||||

||79SA1 [4]|.6|CAM|Verde|

|

||||

||79SA1 [4]|.4|CAM|Avviso|

|

||||

|13SB4|M36 D14||Flc UP||

|

||||

|136B2|M36 D12||FTc DW||

|

||||

|136B3|M36 D13||FiFo incluso In -2||

|

||||

|138B1|M38 D12||FiFo1 Home||

|

||||

|139S2|M39 D12||FiFo1 extra corse grande||

|

||||

|139S3|M39 D13||FiFo2 extra corse corto?||

|

||||

|141B1|M41 D12||FiFo1 Incluso Indietro||

|

||||

|142B2|M42 D13||FiFo2 Incluso In Corse||

|

||||

|139S1|M39 D12||||

|

||||

|139S3|M39 D13||||

|

||||

|137S2|M37 D12||FiFo1 extra corse Scaricare||

|

||||

|137S3|M37 D13||FiFo2 extra corse Scaricare||

|

||||

|136B4|M36 D14||FoTo2 uscite piene||

|

||||

|143B2|M43 D12||uscita M43||

|

||||

|80B2|S1A1 [6]|.13|No FAT||

|

||||

|80B3|S1A1 [6]|.14|No FaT||

|

||||

|145B2|M45 D12||Non uscita FaT||

|

||||

- Inserire controlo inciampo vaso 141B1 / 142B3 / 13683

|

||||

- Carrello 1 tutto allo scarico + mancante botiglie ingresso il motore M38 NON si ferme

|

||||

- 14B2 per chiudere il buco eventuale in ingresso al FIFO2. Stop M39

|

||||

- Carrelli entrambi allo scarico "primo riempimento" M44 fermo con primer vaso su 13683, il FIFO 2 comincia a caricare. Quando la coda > parte M44. Finché il carrello non torna alle 0 la funzione è disattivata.

|

||||

- Carrello: quando si avvicina al tutto vuoto dimezzare la velocità

|

||||

- Tirare via il quickstop

|

||||

|

||||

Calcoli Vari

|

||||

//speed nastri da esterno da usare : dipende dalle ftc

|

||||

//se ftc ingresso è libero considero 0 la speed input

|

||||

//funzione svuotamento bottiglie a carrello in pos minima

|

||||

//se ftc uscita è piena, considero 0 la speed output

|

||||

//formula Speed carrello / catena

|

||||

//CORREZIONE PERCENTUALE speed carrello ** PROVA ***

|

||||

//blocco per svuotamento

|

||||

//limiti speed carrello

|

||||

//formula speed catena (verrà usata solo per la curva)

|

||||

//speed con modo bypass attivo

|

||||

//stop carrello al limite della corsa utile

|

||||

//catene con offset in % rispetto alla speed generale calcolata

|

||||

//l'unica catena che usa velocità calcolata da formula è la catena della curva

|

||||

//CATENA IN/out va a velocità del nastro in/out (con offset in %)

|

||||

//velocità catene in manuale, forzata da hmi

|

||||

//calcolo pos. carrello in % rispetto alla corsa totale

|

||||

|

After Width: | Height: | Size: 905 KiB |

|

After Width: | Height: | Size: 94 KiB |

|

After Width: | Height: | Size: 292 KiB |

|

After Width: | Height: | Size: 30 KiB |

|

After Width: | Height: | Size: 61 KiB |

|

After Width: | Height: | Size: 187 KiB |

|

After Width: | Height: | Size: 246 KiB |

|

After Width: | Height: | Size: 99 KiB |

|

After Width: | Height: | Size: 90 KiB |

|

After Width: | Height: | Size: 41 KiB |